Blog

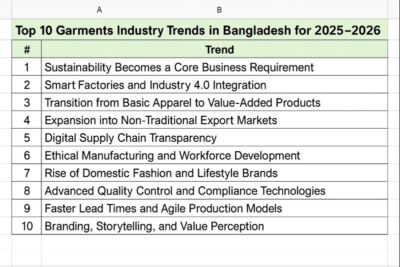

Top 10 Garments Industry Trends in Bangladesh for 2025–2026

Top 10 Garments Industry Trends in Bangladesh for 2025–2026

At Triple, we closely analyze global and regional apparel movements to understand where the industry is heading. This article presents a comprehensive breakdown of the top 10 garments industry trends in Bangladesh for 2025–2026, offering insight for buyers, manufacturers, entrepreneurs, and fashion brands navigating the future of apparel sourcing and production.

garments industry trends in Bangladesh for 2025–2026

1. Sustainability Becomes a Core Business Requirement

Sustainability has moved beyond being a marketing advantage—it is now a fundamental requirement for survival in the global apparel market. The RMG industry in Bangladesh has made notable progress over the last decade, particularly in green factory certification, energy efficiency, and responsible resource usage.

Bangladesh currently leads the world in the number of LEED-certified green garment factories. Between 2025 and 2026, this trend will accelerate further as international buyers demand lower carbon footprints, transparent sourcing, and measurable environmental impact reduction.

Factories are increasingly investing in:

- Organic and recycled cotton

- Water-saving dyeing technologies

- Solar energy and renewable power systems

- Waste recycling and circular production models

For fashion brands, sustainability is no longer optional—it directly influences buyer trust, export opportunities, and long-term brand value.

2. Smart Factories and Industry 4.0 Integration

Technology adoption is reshaping the apparel industry in Bangladesh. As global competition intensifies, manufacturers are turning to Industry 4.0 solutions to improve efficiency, accuracy, and scalability.

Smart factories equipped with automation, IoT-enabled machinery, and AI-powered production planning systems are reducing lead times and minimizing errors. These systems allow real-time tracking of production stages, inventory levels, and quality control metrics.

Between 2025 and 2026, smart manufacturing will no longer be limited to large factories. Mid-sized and export-focused facilities are also investing in digital transformation to stay competitive in international markets.

3. Transition from Basic Apparel to Value-Added Products

Historically, Bangladesh was associated with basic apparel such as T-shirts, trousers, and low-complexity knitwear. However, the industry is rapidly shifting toward value-added and fashion-forward garments.

This includes:

- Embroidered and embellished designs

- Premium woven garments

- Kidswear and modest fashion

- Athleisure and lifestyle apparel

This transition enables higher profit margins and positions Bangladesh as a design-capable sourcing destination rather than just a low-cost manufacturing hub.

Brands like Triple reflect this evolution by blending global fashion aesthetics with high-quality production and attention to detail.

4. Expansion into Non-Traditional Export Markets

While the European Union and the United States remain the largest buyers of Bangladeshi garments, export diversification is becoming a major strategic focus.

Between 2025 and 2026, the Bangladesh garment export industry is expected to grow significantly in non-traditional markets such as:

- Japan

- South Korea

- Australia

- Middle Eastern countries

- Latin America

These markets demand higher quality, compliance, and design differentiation—pushing Bangladeshi manufacturers to elevate standards across the board.

5. Digital Supply Chain Transparency

Transparency is becoming a decisive factor in buyer selection. Global fashion brands increasingly require digital documentation of sourcing, labor practices, and environmental compliance.

To meet these expectations, garment manufacturers in Bangladesh are implementing digital supply chain management systems that provide real-time visibility into production processes.

This shift improves:

- Buyer confidence

- Audit readiness

- Risk management

- Long-term partnerships

6. Ethical Manufacturing and Workforce Development

The role of ethical labor practices remains central to the future of the Bangladesh garments sector. Buyers are prioritizing factories that demonstrate strong commitments to worker safety, fair wages, and skill development.

Investment in workforce training, leadership development, and digital skills is increasing, ensuring that workers are prepared for modern manufacturing environments.

This focus not only strengthens compliance but also improves productivity and reduces labor turnover.

7. Rise of Domestic Fashion and Lifestyle Brands

Beyond exports, Bangladesh’s domestic fashion market is experiencing rapid growth. Rising disposable income, urbanization, and digital shopping habits are fueling demand for locally produced fashion.

Local brands are investing in:

- Premium branding

- E-commerce platforms

- Social media marketing

- Customer experience optimization

This trend creates new opportunities for vertically integrated apparel businesses and strengthens the overall fashion ecosystem.

8. Advanced Quality Control and Compliance Technologies

Quality assurance is evolving through the adoption of AI-driven inspection tools and automated testing systems. These technologies reduce defects, minimize returns, and ensure consistency across large production volumes.

As buyer expectations increase, factories that invest in advanced quality control systems gain a competitive edge in international sourcing decisions.

9. Faster Lead Times and Agile Production Models

The global fashion industry is moving toward shorter product cycles and rapid trend turnover. To keep pace, Bangladeshi manufacturers are adopting agile production models.

These models focus on:

- Smaller batch production

- Flexible manufacturing lines

- Quick material sourcing

- Improved logistics coordination

The result is faster delivery without sacrificing quality—a key factor in maintaining buyer loyalty.

10. Branding, Storytelling, and Value Perception

In 2025–2026, manufacturing excellence alone is not enough. Buyers and consumers want to understand the story behind the product.

Bangladesh’s garments industry is increasingly investing in branding, storytelling, and transparent communication—highlighting sustainability efforts, ethical practices, and innovation.

This shift elevates the perception of Bangladeshi apparel from commodity products to value-driven fashion solutions.

Conclusion: The Future of the Garments Industry in Bangladesh

The top garments industry trends in Bangladesh for 2025–2026 point toward a smarter, more responsible, and more design-focused future. Sustainability, technology, ethical practices, and market diversification are shaping a new era for the apparel industry.

With continued investment and strategic evolution, Bangladesh is well-positioned to remain a global leader in apparel manufacturing for years to come.

At Triple, we align our vision with these industry transformations—delivering fashion that reflects global standards while honoring Bangladesh’s manufacturing strength.

To explore our collections and learn more about our journey, visit

www.triple.com.bd.